Acrylic sheets are a fantastic material for DIY projects, signage, crafts, and even home improvement. They’re durable, versatile, and come in a wide range of colours and finishes. But if you’ve never worked with acrylic before, one of the biggest questions is: How do you cut it safely and cleanly—without cracking or chipping it?

This guide is here to help beginners learn the right tools, techniques, and safety tips to cut acrylic sheets accurately and with confidence.

Why Acrylic?

Before we dive into cutting techniques, let’s quickly look at why acrylic is so popular:

- Lightweight but strong

- More shatter-resistant than glass

- Can be laser cut or hand cut

- Available in clear, frosted, black, white, and coloured varieties

- Affordable and easy to find from local suppliers like CDC Laser

Now, let’s get into the cutting process.

Tools You Can Use to Cut Acrylic

Different projects may call for different tools. Here are the most beginner-friendly options:

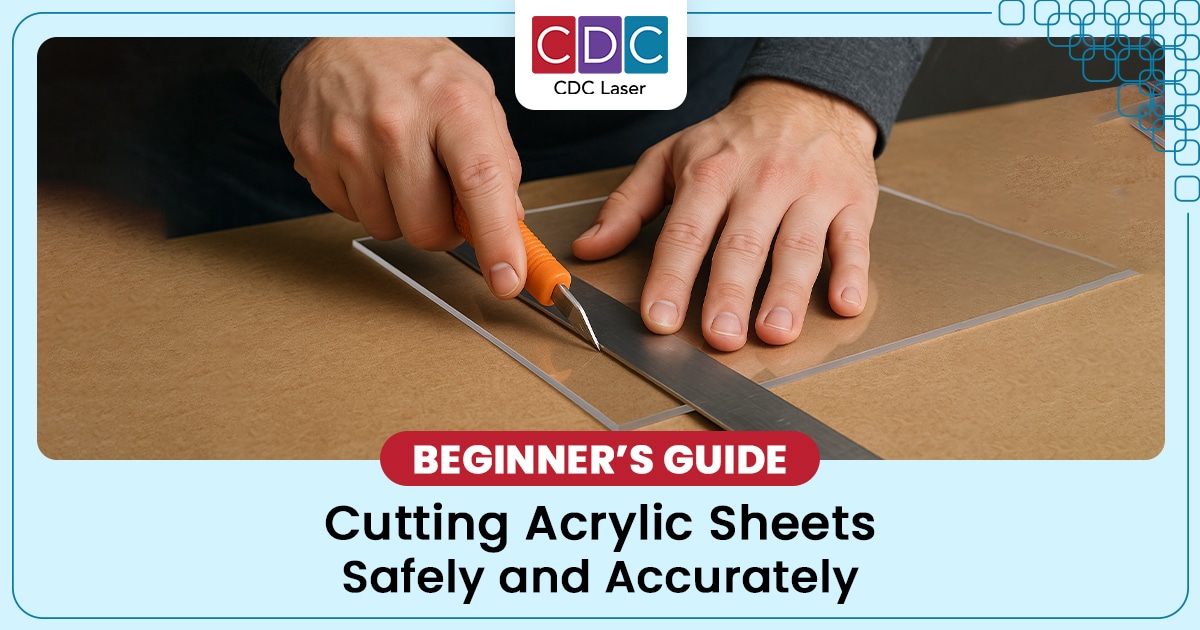

1. Scoring Knife (for thin acrylic sheets)

Best for sheets 2mm or thinner.

- Use a plastic scoring knife (available at hardware stores).

- Place the sheet on a flat surface and run the knife along a ruler several times to score the sheet.

- Flip the sheet and repeat on the other side.

- Snap the sheet cleanly along the scored line.

2. Hand Saw or Jigsaw (for medium thickness)

- Use a fine-tooth blade (such as a metal-cutting blade).

- Secure the sheet with clamps.

- Cut slowly to prevent melting or chipping.

- A jigsaw is great for curves or irregular shapes.

3. Laser Cutter (for high precision)

- Ideal for clean, complex shapes and professional finishes.

- No physical contact = no cracking or rough edges.

- You can design on a computer and have it laser cut by professionals (like CDC Laser).

- Best for signage, intricate patterns, or bulk production.

Step-by-Step Guide to Cutting with a Scoring Knife

Tools Needed:

- Acrylic sheet (2mm or thinner)

- Ruler or straight edge

- Scoring knife

- Safety goggles

- Work gloves

- Flat work surface

Instructions:

- Measure and Mark

Use a permanent marker or pencil to mark where you want to cut. Double-check the size before scoring. - Score the Sheet

Place the ruler along the cut line. Use the scoring knife to cut along the ruler 5–10 times, applying steady pressure. - Flip and Score Again

Turn the sheet over and score the same line on the opposite side. - Snap the Sheet

Place the scored line on the edge of a table and press down firmly to snap the sheet cleanly along the score. - Smooth the Edge (Optional)

Use a fine file or sandpaper to smooth rough edges.

Safety Tips

- Always wear goggles to protect your eyes from flying chips.

- Wear gloves to avoid cuts or abrasions.

- Work in a well-ventilated area if using power tools, as acrylic dust can be irritating.

- Secure your acrylic sheet with clamps to prevent slipping during cutting.

Common Mistakes to Avoid

- Cutting too fast – Can cause cracks or melting

- Using the wrong blade – Always use fine-tooth blades

- Not securing the sheet – Leads to uneven or dangerous cuts

- Skipping safety gear – Acrylic shards can be sharp!

When to Use Professional Cutting Services

If your project involves thick sheets, high precision, or you need multiple identical pieces, consider using a laser cutting service.

Services like CDC Laser offer:

- Clean, polished edges

- Custom shapes and engraving

- Fast turnaround times

- Materials in various thicknesses and finishes

This saves you time, effort, and reduces waste—especially for signage, event displays, or branding.

Conclusion

Cutting acrylic sheets doesn’t have to be difficult or intimidating. With the right tools and techniques, even beginners can achieve clean, professional-looking cuts. Whether you’re making a simple name plaque, a DIY phone stand, or custom home décor, starting with accurate cuts is key to a great result.

And remember, if the job feels too complex or you want a perfectly finished piece, don’t hesitate to use a local laser cutting service like CDC Laser to get the job done.